3Dfect

About this project

Project information

X-ray Computed tomography (CT scan) is a technology that is developed based on conventional digital X-ray technology. In medical application this is used to generate 3-D images of the patients organs used for diagnostics. In industry the technoque is used both on component level for detecting mistakes in asembly and on material level to detect defects in the materials.

Understanding and detecting type, size and location of defects that different manufacturing processes may generate are important both for developing robust processes and for setting e.g. safety margins in the design processes of products. The need to correctly discover and define defects in 3-D is therefore eminent. By defining the defects in 3-D it might be possible to increase the accuracy in the modelling of the component behaviour under loading.

This project is studying the coupling of CT information to FEM calculations in order to better describe the influence of the process on the material properties and thereby build knowledge to improve process control. The project aims at developing a methodology to use the CT model of “real” defects in FEM calculations. In the project, defects primarily in the form of pores are studied with respect to size, form, location and the interaction between these. The project is primarily dealing with metallic materials, both manufactured by conventional methods and by additive manufacturing.

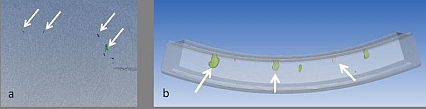

CT-scan of defects in joining, a) friction stirr weld (FSW) of aluminium, b) welding defects in laser weld of steel.